5 Expert Tips to Reduce the Cost of Laser Scanning

As laser scanning technology improves, it’s become critical in construction—eliminating rework and improving building quality. Despite scanning’s growing popularity, it’s not often affordable. The equipment is expensive, costing between $30,000 and $70,000. How can you reduce the costs of laser scanning and stay under budget?

One way to keep costs low is by outsourcing laser scanning, rather than purchasing a scanner. Laser scanning services are affordable, helping you avoid the equipment, software, and labor costs needed to support scanning projects.

Below, we take a closer look at the factors affecting the cost of laser scanning and give you five tips to keep costs low. Plus, we’ll help you define your project scope to eliminate unnecessary work.

Want to learn how laser scanning can minimize rework on your projects? Download our e-book, An Introduction to 3D Laser Scanning.

How Much Does 3D Laser Scanning Cost?

So, how much does 3D laser scanning cost and why does it vary so much? Factors like project size and complexity have a major impact on the cost of scanning, meaning that every project is different.

Here are the primary factors that determine the cost of laser scanning:

- Project size: Project size has the biggest impact on cost. The larger your project, the more scans it will take to complete. To improve your cost estimate, provide the scanning technician with the square footage of the space you want captured. Photos and videos of the site are also useful materials to include—helping you anticipate the cost of scanning and build a more accurate budget.

- Project complexity: Complex projects take longer to scan, increasing costs. For example, it would take a technician longer to scan conduit that measures under an inch than it would a piping system that exceeds two inches in diameter. For a better estimate, communicate the complexity of the area you need scanned.

- Accuracy: Depending on your project, you may need higher accuracy for your scans. Although laser scanners satisfy most accuracy requirements—capturing measurements down to the millimeter—you may need further precision. Depending on your needs, specialized equipment and techniques may be used, raising costs. Choose the lowest level of accuracy you need to meet project requirements—this will help you save money and avoid unnecessary work.

5 Tips to Reduce the Cost of Laser Scanning

Now that you know how much 3D laser scanning costs, how can you save on your next project? With these tips, you can minimize costs and keep your project under budget. Here are five ways to save money on laser scanning:

1. Clearly Define Your Project Scope

To keep costs low, clearly define your project scope. This means describing space you want captured by providing its square footage, photos, videos, and any architectural, mechanical or site plans you have on file. By defining your scope, you can ensure the work being done won’t exceed your needs, keeping costs low.

2. Limit the Area Scanned

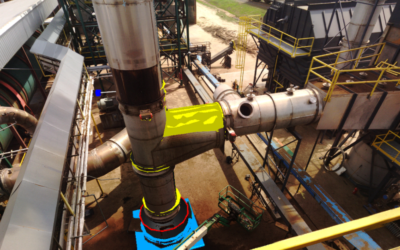

If you only require part of your site to be scanned, restrict scanning to that area to lower costs. When installing a piping system, for example, limit the scan to the area where the piping is going to be installed. Although capturing the entire facility may be helpful, it’s not always necessary to meet your project goals. Restricting the scan to a specific area will reduce costs and support your bottom line.

3. Be Realistic About Accuracy

Be realistic about the level of accuracy you need to complete your project. If you need to capture pipes greater than 2”, for example, then you should choose a lower level of accuracy for your scans. By specifying a level of accuracy that meets your project needs, you can eliminate unnecessary costs and stay under budget.

4. Choose the Right Deliverables for Your Project

The bulk of the project cost is often in the deliverables. If you request that your 3D model contain every component captured during scanning, this raises costs, and is often unnecessary. In fact, you can extract many deliverables directly from the point cloud, including clash detection, floor flatness analysis, pre-fabrication, and wall plumbness. Being selective about the deliverables you request will reduce costs and help you stay within budget.

5. Communicate Details About Site Access

For efficient scans, communicate the best time to access the site to the technician. You should also mention factors like safety training, PPE, or security clearance requirements that may affect the scan. With this information, the scanning technician can create a site access plan to scan the site as quickly as possible. This will help you ensure the scanning process is efficient—eliminating change orders caused by return visits.

Ready to Save Money on Your Next Project?

Considering using laser scanning on your next project? Schedule a free, one-on-one demo with our experts to learn how 3D scanning can help you minimize rework and other setbacks, helping you keep your project on schedule and under budget. You’ll learn how 3D scanning works and how it streamlines productivity and eliminate delays. Request a demo today.