What is 3D Laser Scanning?

With today’s technically complex construction environments and challenging regulatory requirements, accuracy is critical to project planning. General contractors, project managers, and architects need exact site conditions to coordinate field teams effectively and avoid project hiccups. 3D scanning services offer project heads a way to attain exact existing site conditions with no margin for error.

How do 3D laser scanners work?

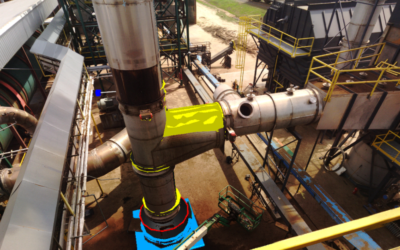

3D laser scanning (also referred to as 3D imaging, laser scanning, or 3D reverse engineering) is the process of capturing digital information about the shape of an object with non-harmful laser light. 3D scanning systems like the Faro Focus capture millions of high-quality images, down to the smallest details.

The laser scans are then stitched together to create point cloud data which can then be used as a virtual tour of your project, merged into a 3D CAD Model, and ultimately in clash detection and BIM workflows. This process is often referred to as scan to CAD or scan to BIM.

Scan to BIM is especially well suited for measuring and inspecting large construction projects where traditional methods would be time-consuming and leave too much room for human error. By using laser scanning services in tandem with 3D models, your field teams reach new levels of productivity in a seamless and connected construction workflow.

When do you use a 3D Laser scanner?

3D laser scanning is best used at the beginning of your construction project. Taking a 3D scan at the onset will give your field teams technically precise site conditions and high-resolution visuals they can rely on to create drafts. This avoids trade clashes, prevents problems, and saves time and money before the project even starts. Too often field teams run into early project complications due to inaccurate blueprints leading to costly work order changes and project delays.

This is even truer for teams spread out across the country or in different locations. The 3D laser scanning file can be used to hold virtual meetings, providing teams off-site with a structural overview, wall, ceiling, and mechanical space dimensions, and also the ability to process field verifications when needed. Using scan to CAD, project leads can even test out the appearance and fit of new objects in the area, whether it’s office furniture or new equipment.

Project managers and general contractors also see great value in periodic scans with projects that require a large amount of coordination or are technically complex. With periodic scans, BIM specialists and field teams can validate information on demand, resolving coordination problems with ease.

When field teams run into complications, laser scanning can also be used to troubleshoot projects. With an exact 3D model of the site conditions, project managers can coordinate their teams to ensure that project plans don’t conflict further.

What are the benefits of 3D Laser Scanning?

The three main benefits of laser scanning are accuracy, speed, and cost:

- Accuracy: Ensuring that construction plans are up to code can be stressful, especially on projects that have a lot of moving pieces. Measurements taken with a tape measure or handheld device are subject to error, leading to regulatory risk. With 3D laser scanning technology, project managers have the most accurate measurements possible, down to the millimeter. Project managers can rest easy knowing that their data is correct and easily shareable, eliminating any guesswork or need to re-measure.

- Speed: One laser scanner can do in a day what would take a team of 2-6 one week. By capturing millions of data points per second, 3D laser scanners provide rich details in every aspect of your project without time-consuming manpower.

- Cost: 3D laser scanners provide project managers with cost savings in two main ways, reduced manpower and decreased project hiccups. On-site manpower is costly. As mentioned above, laser scanners dramatically reduce the manpower required during the measuring process. Depending on the project size, these costs can add up quickly. As you can see in the NYC example, using a laser scanner would have reduced the measurement costs by 75%. 7) Additionally, trade clashes can also be costly, leading to expenses in equipment rentals, trade materials, and project delays. By starting with exact site conditions, teams can plan and coordinate effectively, preventing costly disruptions.

What types of projects is 3D Scanning used for?

As noted in KPMG’s global construction survey, in the past decade construction leaders have been realizing the value of emergent technologies and have been looking for ways to harness their potential. As a result, 3D scanning and other technologies have expanded to each piece of the construction process. Architects, civil engineers, sheet metal workers, and fire safety professionals all are using 3D scanning in their project management to form better decisions, foster collaboration, and make well-informed decisions. We’ve seen applications in building information modeling (BIM), virtual design construction (VDC), pre-construction as-builts, quality control, plant and industrial measurements, progress monitoring, field data collection & verifications, and to capture high-resolution images.

If you’re a contractor looking for a competitive edge, 3D laser scanning might be the answer. To see if it is a fit for you, contact our team: