How Does 3D Scanning Help with Site Monitoring?

3D Scanning services have significantly improved the site monitoring process for construction companies—enabling them to conduct monitoring at lower costs and with higher levels of accuracy. With the use of this technology, developers can create virtual models of project structures to remotely monitor construction progress. The remote monitoring capabilities offered by 3D laser scanning translate into reduced costs and a more robust method of tracking changes made to the project site.

Why Are 3D Scanning Services Important for Virtual Site Monitoring?

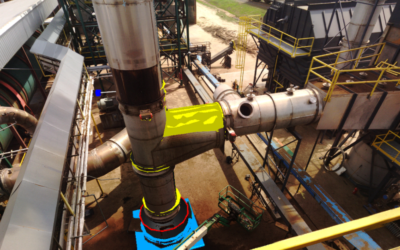

The process of 3D scanning involves using a laser to capture the coordinates of different surfaces and structures—collecting millions of points to form a detailed digital representation of the objects being scanned. These collections of points form what is commonly referred to as a “point cloud.” This data, once converted into a digital form or a Building Information Model (BIM), offers a way for developers to stay informed about any changes happening to the project site virtually, eliminating the need for developers to be physically present at the site.

→ Download Now: Guide to Scanning [Free eBook]

There are several distinct advantages offered by remote site monitoring, including:

Transparency

Disputes between project stakeholders are common, particularly when dealing with larger scale projects. By using 3D scanning to create a digital representation of the project site, transparency can be ensured, as all stakeholders are given equal access to the information they need to monitor site progress. Providing the same virtual representation of the project site to all stakeholders eliminates potential disputes because it allows them to view the same information, leading to fewer misunderstandings and increased accountability.

Safety

There are many risks associated with site work, as construction sites are often dangerous. According to one source, the construction industry has the highest number of fatalities out of any industry, accounting for over 18% of all fatal occupational injuries. By taking advantage of 3D scanning services to create a digital model, developers can avoid some of the safety risks that come with being present on construction sites when conducting site monitoring.

Audit Trails

Another advantage offered by 3D scanning software includes the ability to create visual audit trails. Once scanning takes place and a digital model of the project site has been created, any changes made to the site are recorded. This means that developers can reference a visual record of all changes made to the project and perform future audits based on the digital documentation that they have created.

Creating digital representations of sites is not just helpful for live site monitoring, but also for comprehensive record-keeping. If necessary, developers can consult the history of the site to ensure the quality of their work and defend themselves against potential defect claims. The ability to revisit detailed visual records of site progress enables developers to guard against potential errors and ensure full compliance with regulations.

What Are the Major Cost Benefits of 3D Scanning When Site Monitoring?

One of the major advantages that 3D scanning has over traditional methods of surveillance during site monitoring is its low cost. This is because 3D scanning allows developers to spend less time recording site data and reduces the number of change orders that must be made during the project. Laser scanning is an accurate, inexpensive way to capture and update as-built information as construction progresses.

While monitoring a site, developers can reduce their costs by choosing laser scanning over more traditional surveillance methods. This is because one 3D scanner can capture millions of data points per second—achieving the same results in one day as a team of several technicians could accomplish in a full week. Site monitoring with the use of laser scanners reduces the overall time spent monitoring, meaning lower costs for project stakeholders.

Change orders can result in project delays and huge cost overruns. With the use of 3D scanning to generate BIM models, developers can detect and eliminate potential issues ahead of time. This is because clash detection is a part of the BIM modeling process, allowing developers to identify trade clashes that might impede the progress of the project. By integrating scan-to-BIM into the site monitoring process, developers can avoid costly change orders that may result from inaccurate project plans.

The benefits of 3D scanning can be seen throughout the entire site monitoring process. From enabling virtual monitoring to reducing costs, 3D scanning optimizes site monitoring for developers.

If you are a contractor looking to reduce costs, 3D laser scanning might be the answer. To see if laser scanning fits your needs, contact our team: