3D Scanning for Remote Coordination Capabilities

A Summary of Our Conversation with Faro

During the height of the coronavirus pandemic, construction experienced a forced digital transformation that disrupted many day-to-day operations. Visiting project sites during preconstruction and holding face-to-face meetings became out of the question. Our 3D scanning services filled this gap and gave clients the flexibility needed to adjust to constant change. John Brown, our Head of 3D Scanning, sat down with the team at Faro to discuss two specific examples that illustrate how.

Designing with a 3D Scan

Recently we had the pleasure of collaborating with the team at Animal Arts. Animal Arts, a Colorado-based architectural firm specializing exclusively in the design of animal care facilities, was redesigning an animal shelter in Long Island, New York. Originally the architects had prepared to fly out to the site, measure the building, and meet with their clients. The COVID crisis inhibited these plans. No longer able to capture the information on their own, the team needed a way to visit the site from their offices in Boulder. Our scanning services provided this and more.

When you get faced with challenges, sometimes you find a better way of doing something

Heather Lewis, a Principal at Animal Arts

When speaking with Heather Lewis, a Principal at Animal Arts, Heather pointed out three main benefits her team saw immediately: quickened deliverable turnaround times, perfect measurements, and up to date as-built prints to work off. Using the 3D scan, the team at Animal Arts designed, measured, and coordinated their work from almost 2,000 miles away. “When you get faced with challenges, sometimes you find a better way of doing something,” Heather said. “I think this is a great solution for the future as well as for this year.”

Using 3D scanning to troubleshoot and fix

Next, John discussed another recent example that showcases the remote coordination capabilities of 3D scanning. A manufacturing facility in rural Georgia experienced a disruption of their machinery caused by a misalignment of the main exhaust stack. The management team, located in western Pennsylvania, reached out to our 3D scanning professionals for assistance. The misalignment occurred at the base of the stack and at the main line’s connection point. Unfortunately, travel for the facility’s management team was not feasible. Like Animal Arts, they needed a way to visit the facility in Georgia without traveling there. Our 3D scanning team provided a solution by using the scan data to create a 3D virtual tour.

In addition to coordinating the project, our draftsmen and BIM coordinators were also able to design a fix for the stack using the scan. Fixing the stack required a crane and major shutdowns to the facility’s operations. To make sure things would go off without a hitch, our team layered the new plans into the 3D scan. From this view, the management team could make sure that the new machinery fixed the problem correctly.

The ROI of 3D Scanning is real

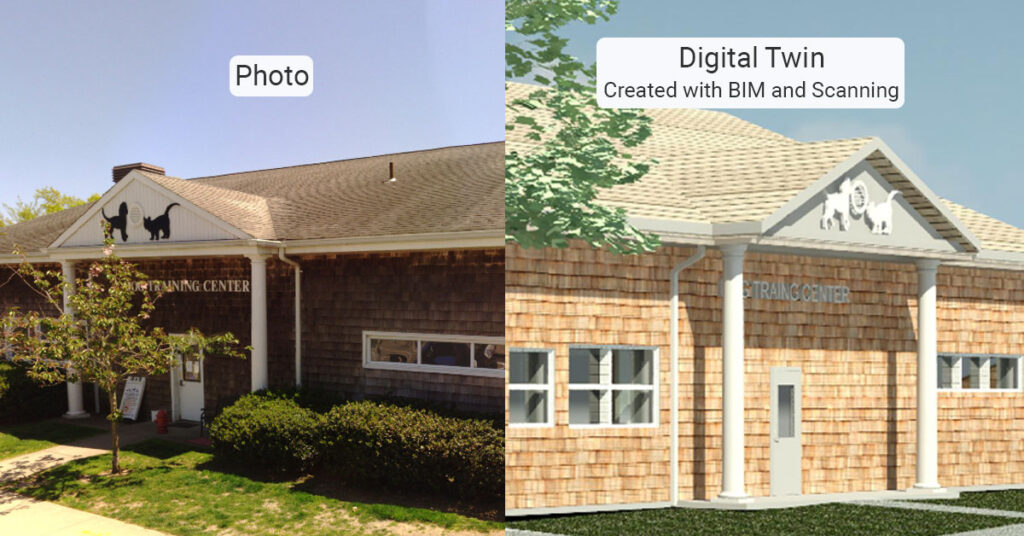

In both examples, 3D scanning proved extremely helpful for teams separated by a far distance. The exact digital replica created with the combination of laser technology and a high-resolution camera captures every detail of a designated area. This information is a powerful tool for taking additional measurements, annotating plans, and collaborating. With 3D scanning, companies have the agility they need to adapt to today’s remote requirements and a way to make operations more efficient in the future.